Material school - Tencel

Tencel is a brand-name for a fibre called lyocell; it’s human-made and consists of cellulose harvested from eucalyptus trees. Tencel is produced by the Austrian company Lenzing AG that has won the European Award for the environment from the European Union for their unique developing process.

Ever turned a garment inside out and not really understood what type of fabric it is made of?

Within the textile industry, there is a riot of names on fabrics and hard to know what’s what.

Here we will over time go through the most commonly used fabrics and materials within our industry, the process they go through to become finished products, what qualities they have and the footprint they leave on our planet.

What:

Tencel is a brand-name for a fibre called lyocell; it’s human-made and consists of cellulose harvested from eucalyptus trees.

Tencel is produced by the Austrian company Lenzing AG that has won the European Award for the environment from the European Union for their unique developing process.

Where: Austria

Tencel fibre.

How:

Tencel or Lyocell is created using a solvent spinning technique.

The first step is preparing the wood pulp. The trees grown for lyocell production are harvested and sent to a factory. The trees get cut into shorter lengths and are debarked using high-pressure jets of water. The logs are chipped into little squares and put into a vat of chemical digester that softens them into a wet pulp. The pulp is then washed and dried.

After preparing the wood pulp, the cellulose needs to be dissolved. At the lyocell factory, the workers will unroll spools of cellulose and split them into one-inch squares. The workers will load the squares into a heated, pressurised vessel filled with amine oxide. Soaking in the solvent, the cellulose dissolves into a clear solution. To ensure that all the chips dissolved it is pumped out through a filter.

The next step is spinning.

The dissolved chips get pumped through something called spinnerets. The spinnerets have small holes, and when the cellulose comes through it, long strands of fibre come out. The fibres need to go through another round of amine oxide, this time diluted, then they are washed with de-mineralised water. Depending on the future use, a lubricant, that may be soap or silicone is applied to the fibre. This is done to make the carding and spinning into yarn easier.

The final steps.

The fibres are now a large untwisted bundle of continuous length filaments, a form called tow. The tow is sent to a crimper, where the fibre gets compressed, giving it texture and bulk. Next up is carding, where the threads go through a process similar to combing, to separate and order the strands. The strands are then shipped to a fabric mill, where the lyocell can be processed in different ways. It may be spun together with other fibres such as wool or cotton. The yarn can be woven or knitted.The amine oxide in the production of lyocell is recovered and re-used, 99% of the amine oxide is recoverable in the manufacturing process.

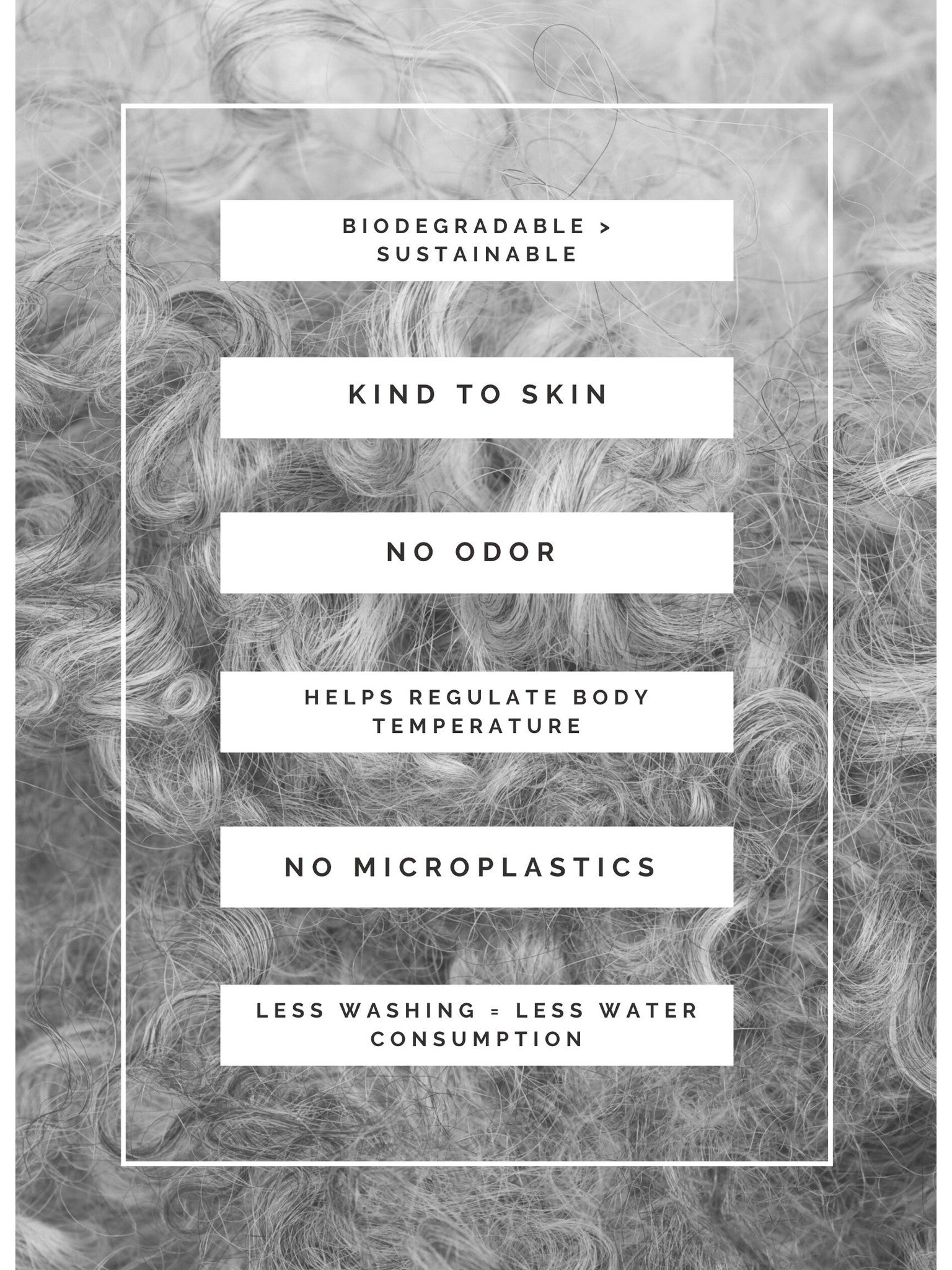

Benefits:

Soft

Absorbent

Strong when wet and dry

Wrinkle resistant

Biodegradable.

T-shirt in Wool/Tencel mix.

bilde her.

Sustainability:

Tencel is considered a highly sustainable material, but as most textiles, it also has some impact on the environment.

The manufacturing of Tencel requires less energy and water than most fabrics. The solvents used in the lyocell production are made using petrochemicals. However, the closed loop production process means that the solvents are recycled time and time again to produce new fibres and minimise harmful waste. Being a naturally derived fibre, Tencel is biodegradable. Lenzing source its wood and pulp from certified and controlled sources in sustainably managed plantations.The main concern with Tencel is the use of energy; Lenzing AG has addressed this and is working on it by increasing their use of renewable energy source.

The manufacturing of Tencel requires less energy and water than most fabrics. The solvents used in the lyocell production are made using petrochemicals. However, the closed loop production process means that the solvents are recycled time and time again to produce new fibres and minimise harmful waste. Being a naturally derived fibre, Tencel is biodegradable. Lenzing source its wood and pulp from certified and controlled sources in sustainably managed plantations.The main concern with Tencel is the use of energy; Lenzing AG has addressed this and is working on it by increasing their use of renewable energy source.

Our new line Foss is made in a Merino Wool/Tencel mix to make the garments even more durable whilst following our vision of being a sustainable brand.

Sources:

Tencel.com

http://www.madehow.com/Volume-5/Lyocell.html